Filtration technology

Filtration: our core competency – your factor of success, thanks to

// pure cooling lubricant at the tool cutting edge

// increased finish quality of the machining

// avoidance of damage to the pump and therefore expensive downtimes

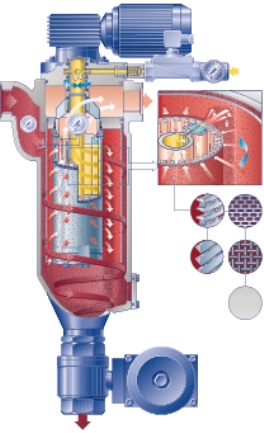

Reversing flow automatic filter

The low-maintenance, reversing flow automatic filter is suitable for full and partial flow filtration of all materials and cooling lubricants.The medium flows through the filter from the outside to the inside, dirt sticks to the outside of the sintered stainless steel braided fabric and falls down. The filter is cleaned automatically by backwashing with air or its own medium. Thanks to different sizes and combinability, both small and very high flow rates can be filtered effectively, in a medium-free and process-safe way.

Cascading filter

The cascading filter consists of a pre-filter and a fine filter that clean the medium as it passes through. The medium first passes through the coarse pre-filter (mesh density approx. 500 μm) that must be washed from time to time. This forms a filter cake which increases separation efficiency and filter fineness. In a second step, the pre-cleaned medium passes through the fine filter. Purities up to 20 μm can be obtained. The fine filters used are either washable wire mesh elements or exchangeable units (fibreglass). This filter is designed specifically for high flushing capacities.

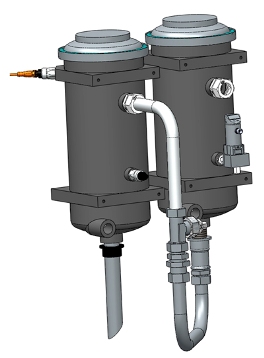

Exchangeable filter

With regard to the acquisition costs, the exchangeable filter in the form of cartridges or bag filters are the cheapest alternative. The filtration capacity generally depends on the medium. Depending on load and contamination, the upkeeps may therefore be quite high. Exactly for this reason, the use of exchangeable filters is avoided for the full or partial flow filtration of the machine tank, they are usually used as pre-filters or secondary filters to protect the pump and other devices. With regard to the filter fineness, the exchangeable filter is very flexible with purities of up to 2 μm.

Our exchangeable filter element – three-times increased surface for maximum filtration

Based on our own innovative strength and competence, we‘ve developed our own filter elements for spin-on filters. The conventional commercially available solutions were unable to meet our expectations in terms of service life and medium purity.The M-Tech spin-on filter element is unique in the compact high-pressure units class. The three times larger filter surface guarantees even greater efficiency – because more filter surface means less cleaning! Not only that, but the wire mesh element is washable and can even be cleaned in an ultrasonic bath. No disposal is required, as is needed with bagfilters for example. That‘s sustainable and also reduces operatingcosts. These filters are standard in the compact coolinglubricant high-pressure filtration solutions.

Benefit from our own developed filter element:

- High medium purity (40 – 60 μm)

- Improved service life, less machine downtime

- Cost savings, increased efficiency

- No throwing away like with bag filters