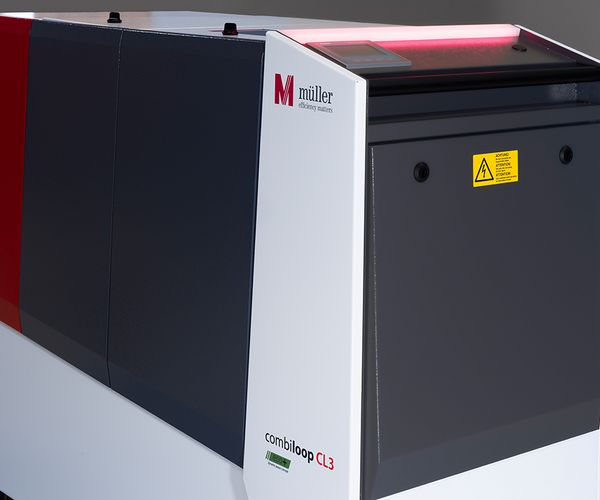

combiloop CL3G

BEST-IN-CLASS HIGH-PRESSURE SYSTEM. FOR MORE MONEY IN YOUR POCKET!

Temperature stability and extremely economical with oil. The smallest footprint for flushing capacities of up to 60 l/min in the emulsion. Sustainability and Industry 4.0 safety features as well as a 250 l clean liquid tank integrated as standard. Your benefit? Maximum service life, maximum operating cost reduction, noticeable production area optimisation. With maximum process reliability. combiloop CL3 G – the high-pressure system for all those who already stand for progress and the future in high-pressure cutting with cooling lubricants.

Suitable for lathes by:

Citizen, DMG Mori, Manurhin, Star, Tornos, Tsugami, to name but a few.

| Technical data | |||

|---|---|---|---|

| Equipment |

| ||

| Flow rate, depending on the configuration |

| ||

| Pressure |

| ||

| Filter / Filter fineness |

| ||

| Operation |

| ||

| Service connections |

| ||

| Features |

| ||

| Degree of machine contamination more |  | ||

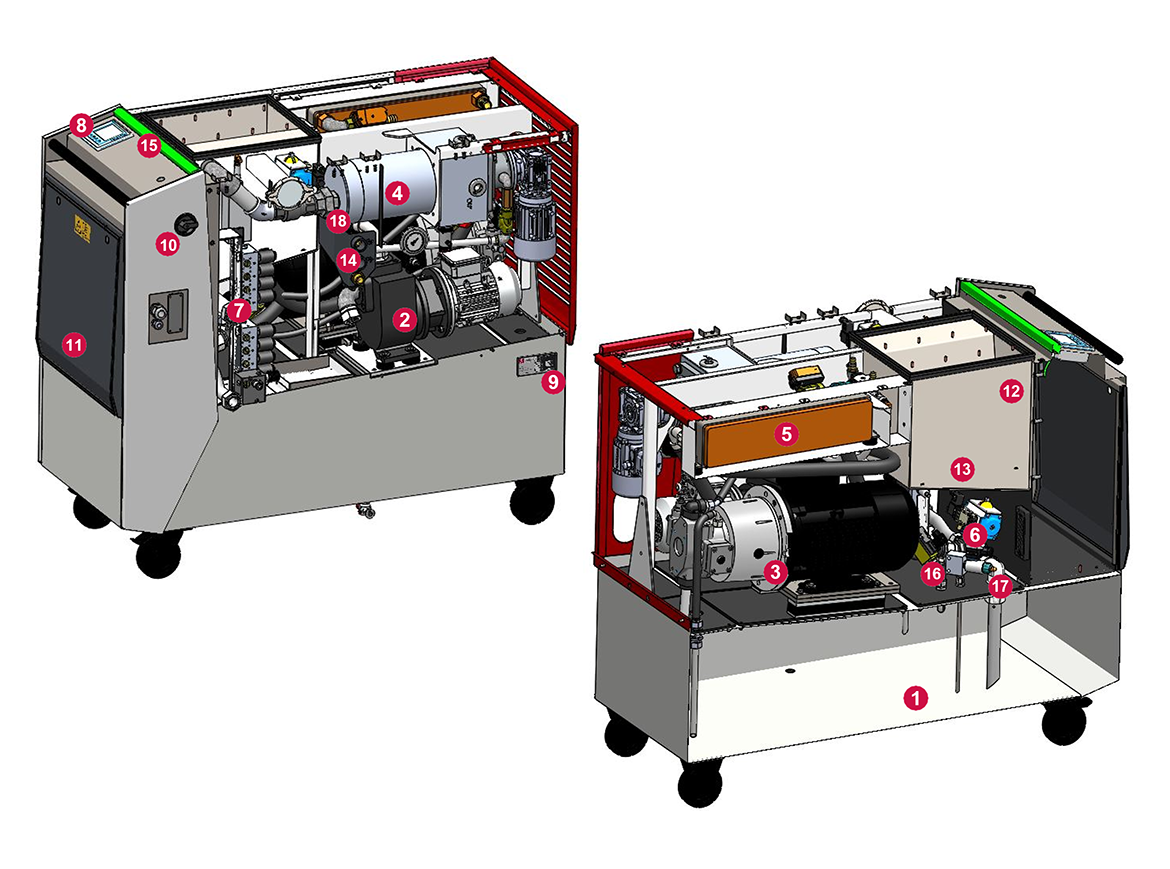

FUNCTION

Caption:

- Modern housing with 250-liter clean liquid tank

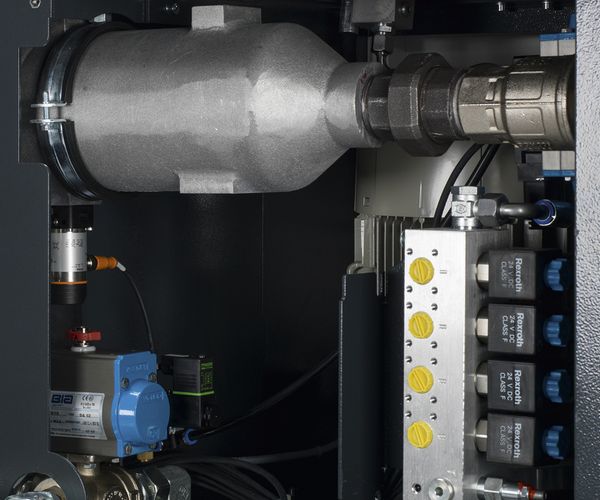

- Transfer pump for filter cycle

- eco+ high-pressure pump in control pump technology

- Self-cleaning automatic filter (option)

- Plate heat exchanger

- Ball valve for bypass filtration (changes over when clean liquid tank is full)

- Valve block with controllable service connections

- Touch panel for system operation

- Type plate

- Main switch

- Electronic control unit (not visible)

- Flushing tank

- Collecting strainer basket for filter sludge (not visible)

- Compressed air connection

- LED status indication

- Flow sensor

- Pressure control

- Supply and return of cooling water for the plate heat exchanger

DOWNLOADS

Interested?

Please give us a call or send us an email. We are looking forward to helping you.

phone: +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de