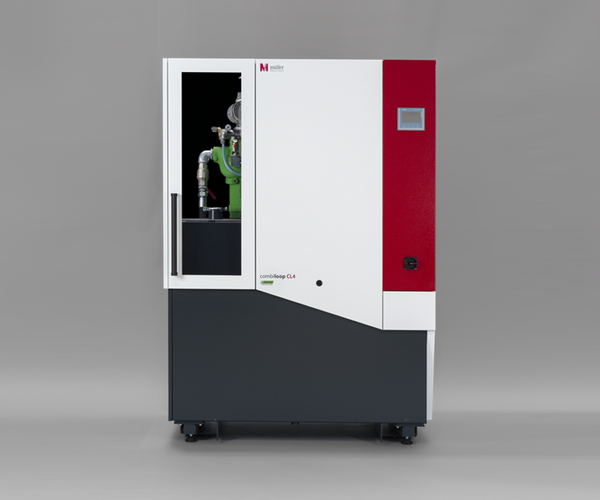

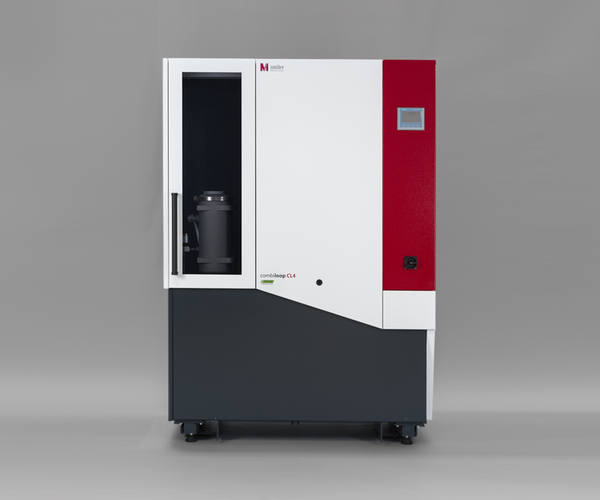

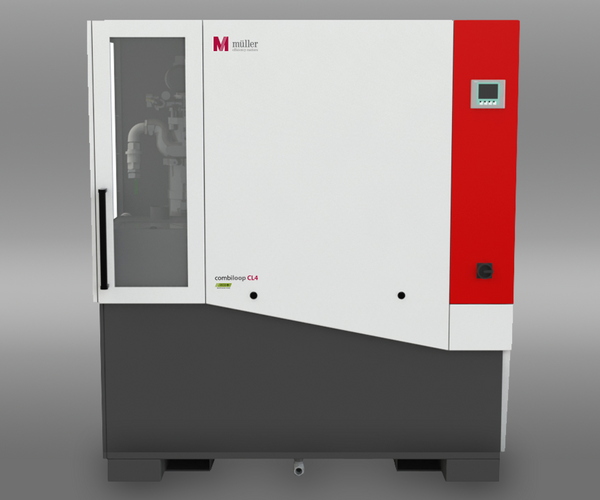

combiloop CL4G

A STANDARD WITH A HIGH LEVEL OF INDIVIDUALISATION

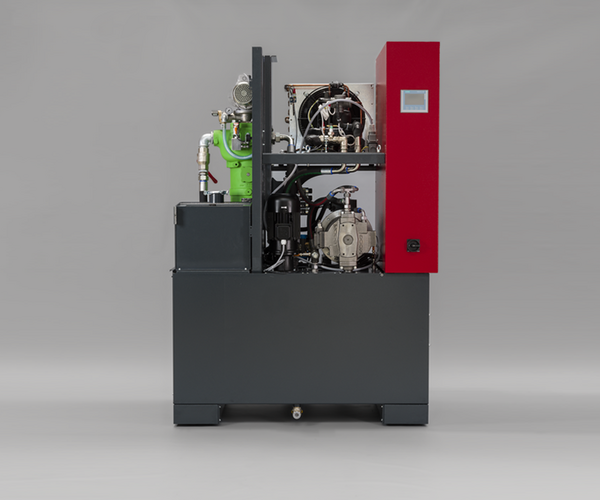

You need high performance flushing? And there are fine chips and a high contamination level on your machine? Your standard is the highest surface quality? Then the combiloop CL4G is a must. Based on three sizes of clean liquid tank, it provides high-pressure and bypass or full flow filtration. In addition, thanks to its intelligent modular design, it can be modified to optimal effect to your filtration, flushing, and cooling needs. The combiloop CL4G makes individualisation the standard!

Suitable for lathes by:

Citizen, DMG Mori, Manurhin, Star, Tornos, Tsugami, to name but a few.

| Technical Data | CL4G-400 | CL4G-600 | CL4G-800 | |

|---|---|---|---|---|

| Equipment |

|

|

| |

| Connections |

| |||

| Pumps |

|

|

| |

| Flow rate and pressure |

|

| ||

| Filtration / Filter fineness |

|

| ||

| Operation |

| |||

| Service connections |

| |||

| Degree of machine contamination more |  | |||

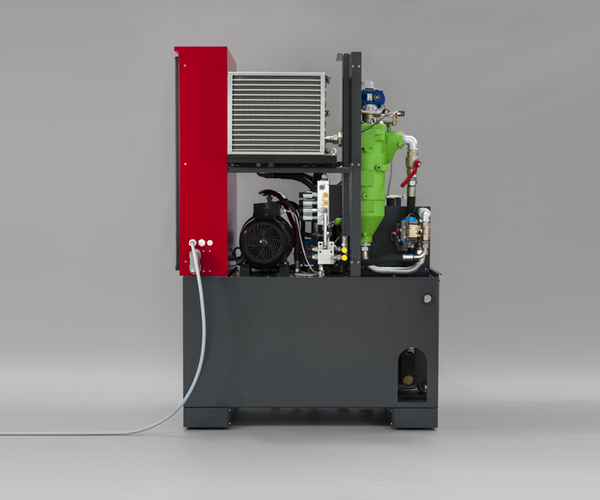

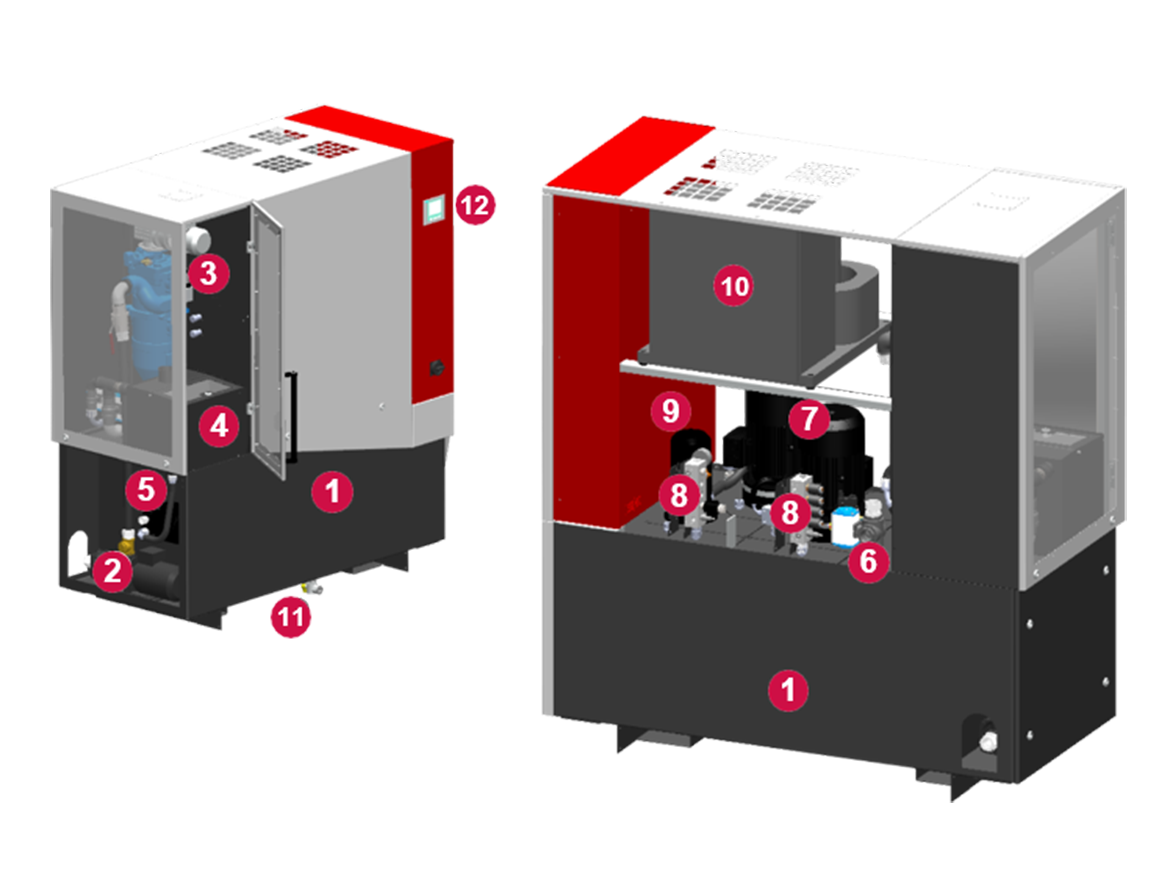

FUNCTION

Caption:

- Clean liquid tank

- Reciprocating pump for filter cycle

- Self-cleaning automatic filter (option)

- Flushing tank with wire mesh collector for filter sludge

- Recirculation pump, flushing tank (option)

- Bypass filtration (option)

- eco+ high-pressure pump with self-regulating piston pump technology / low-pressure pumps (to pump configuration)

- Valve block with controllable service connections

- Cooling circuit pump (option)

- Cooling system / panel heat exchanger (option)

- Drain tap

- Electronic control with touch panel for system operation

DOWNLOADS

Interested?

Please give us a call or send us an email. We are looking forward to helping you.

phone: +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de